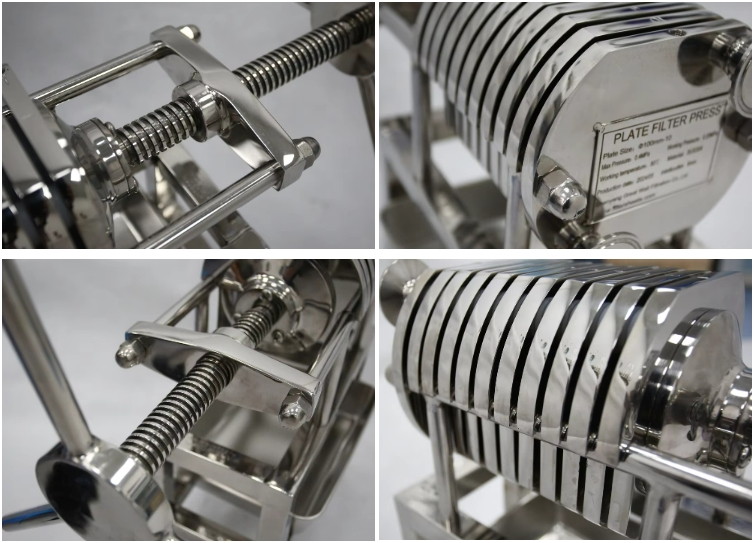

Stainless steel plate and frame filter without pump

Operating principle

Before work filter cloth covers in the filter plate,and then operating pressure filter, drivencompaction pole, will pressure plate tightly pressure filter plate tight. Starting feeding pumpthrough feed material mouth input pressure filter, the material through the filter plate into thechannel filter room, under the function of feeding pump pressure, clear liquid through filter clothinto the filter plate cloudy round bullet point filter face. Then through the way of filter plate aftercollection by a liquid mouth outflow. And filter cake interception in the room, until the cake fulwith filter room,then stop feeding pump, release the pressing plate, the filter plate piece bypiece to pull to pressing plate direction unloading frame in the cake, then back into the nextwork cycle.

Product details

Equipment parameters

| Product Name: | Stainless steel plate and frame filter |

| Model number | RFP100-10 |

| Filter sheet used | 10pcs |

| Filtration area | 0.078m² |

| Filter Chamber Volume | 0.3L |

| Reference Flow Rate | 0.2T/h |

| Pressing method | Manual screw tightening |

| Feed pump | Explosion-proof sanitary pump |

| Pipeline connection | Quick release clamp |

| Caster wheels | Fixed casters |

| Material | SUS316L |

| Sealing ring, gasket | Silicone Rubber |

| Filter size | Φ100 mm |

| Thickness | Filter plate 12mm, filter frame 12 mm |

| Inlet and outlet diameter | Φ19mm |

| Machine size | 500×350×600 mm |

| Working pressure | ≦0.4 MPa |

| Temperature | ≦ 80 ℃ |

| Filter material | Depth filter sheet and filter paper |

Note: Before starting filter, ensure there is no miscellaneous personnel nearby, and ensure there is no foreign matter between filter plates.

Contact us for more information, we will provide you better products and best service .