Reasonable price Liquid Filter Sheets - Creped Filter Papers with large filtering area – Great Wall

Reasonable price Liquid Filter Sheets - Creped Filter Papers with large filtering area – Great Wall Detail:

Creped Filter Papers Applications:

Great Wall filter paper includes grades suitable for general coarse filtration, fine filtration, and retention of specified particle sizes during the clarification of various liquids. We also offer grades that are used as a septum to hold filter aids in a plate and frame filter presses or other filtration configurations, to remove low levels of particulate, and many other applications.

Such as: production of alcoholic, soft drink, and fruit juice beverages, food processing of syrups, cooking oils, and shortenings, metal finishing and other chemical processes, refinement and separation of petroleum oils and waxes.

Please refer to the application guide for additional information.

Creped Filter Papers Features

•Uniformly creped surface with cellulose fiber pre-coat for a larger, more effective surface area.

•Increased surface area with a higher flow rate than standard filters.

•High flow rates can be maintained while effectively filtering, so filtration of high viscosity or high particle concentration fluids can be performed.

•Wet-strengthened.

Creped Filter Technical Specifications

| Grade | Mass per Unit Area(g/m²) | Thickness(mm) | Flow Time(s)(6ml)① | Dry Bursting Strength (kPa≥) | Wet Bursting Strength(kPa≥) | Color |

| CR130 | 120-140 | 0.35-0.4 | 4″-10″ | 100 | 40 | white |

| CR150K | 140-160 | 0.5-0.65 | 2″-4″ | 250 | 100 | white |

| CR150 | 150-170 | 0.5-0.55 | 7″-15″ | 300 | 130 | white |

| CR170 | 165-175 | 0.6-0.7 | 3″-7″ | 170 | 60 | white |

| CR200 | 190-210 | 0.6-0.65 | 15″-30″ | 460 | 130 | white |

| CR300K | 295-305 | 0.9-1.0 | 8″-18″ | 370 | 120 | white |

| CR300 | 295-305 | 0.9-1.0 | 20″-30″ | 370 | 120 | white |

①The time it takes for 6ml of distilled water to pass through 100cm2 of filter paper at temperature around 25℃

How Do Filter Papers Work?

Filter papers are actually depth filters. Various parameters influence their effectiveness: Mechanical particulate retention, absorption, pH, surface properties, thickness and strength of the filter paper as well as the shape, density and quantity of particles to be retained. The precipitates deposited on the filter form a “cake layer”, which – depending on its density – increasingly affects the progress of a filtration run and decisively affects the retention capability. For this reason, it is essential to select the right filter paper to ensure effective filtration. This choice also depends on the filtration method to be used, among other factors. In addition, the amount and properties of the medium to be filtered, the size of the particulate solids to be removed and the required degree of clarification are all decisive in making the right choice.

Great Wall pays particular attention to continuous in-process quality control; additionally, regular checks and exact analyses of raw material and of each individual finished product assure constant high quality and product uniformity.

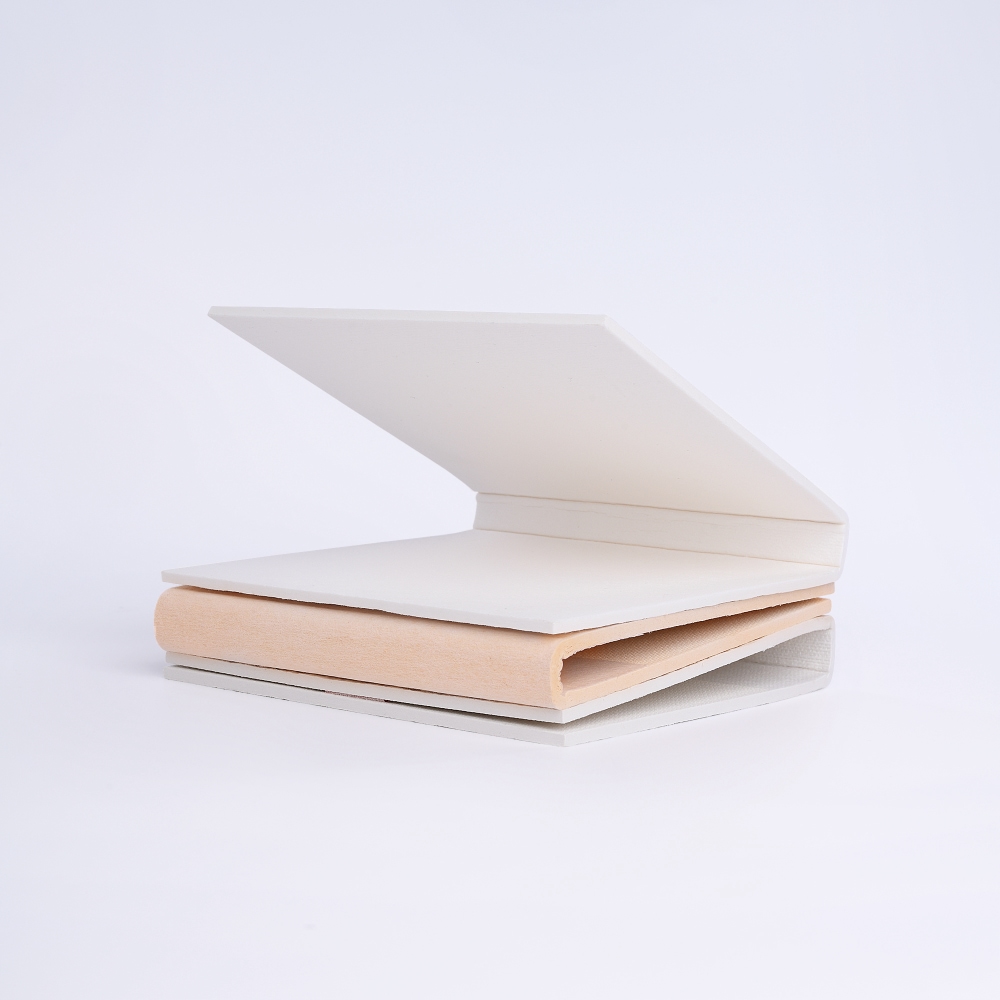

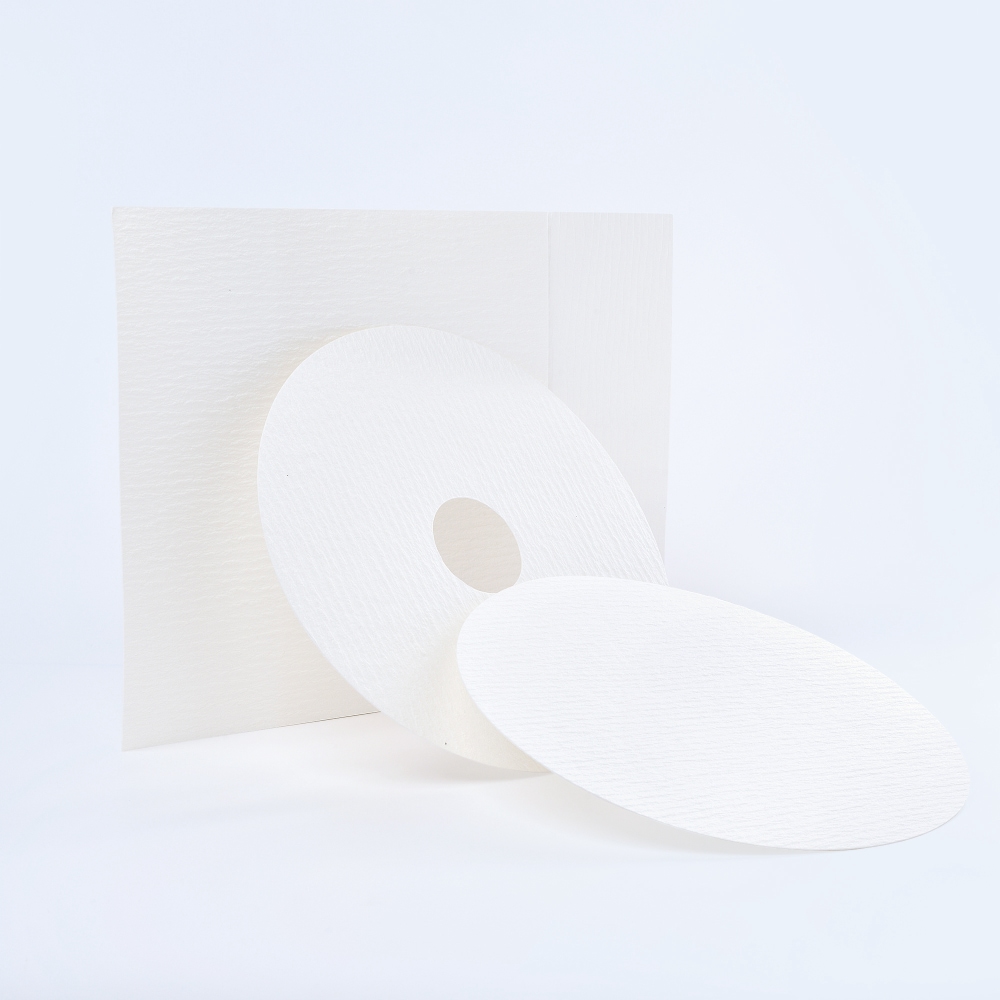

Product detail pictures:

Related Product Guide:

It truly is our responsibility to fulfill your requirements and successfully provide you. Your fulfillment is our best reward. We're seeking forward in your check out for joint development for Reasonable price Liquid Filter Sheets - Creped Filter Papers with large filtering area – Great Wall , The product will supply to all over the world, such as: Malta, British, Russia, Profession, Devoting are always fundamental to our mission. We have always been in line with serving customers, creating value management objectives and adhering to the sincerity, dedication, persistent management idea.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!