The production of organosilicon involves very complex processes, including the removal of solids, trace water, and gel particles from intermediate organosilicon products. Typically, this process requires two steps. However, Great Wall Filtration has developed a new filtration technology that can remove solids, trace water, and gel particles from liquids in one step. This innovation allows organosilicon manufacturers to simplify their processes, and the ability to quickly and reliably remove water from another liquid is an ideal characteristic that reduces by-product waste and improves production efficiency.

Background

Due to the unique structure of organosilicon, it possesses the properties of both inorganic and organic materials, such as low surface tension, small temperature coefficient of viscosity, high compressibility, and high gas permeability. It also has excellent properties such as high and low-temperature resistance, electrical insulation, oxidation stability, weather resistance, flame retardancy, hydrophobicity, corrosion resistance, non-toxicity, and physiological inertness. Organosilicon is mainly used in sealing, bonding, lubrication, coating, surface activity, demolding, defoaming, foam inhibition, waterproofing, moisture-proofing, inert filling, etc.

Silicon dioxide and coke transform into siloxane at high temperatures. The resulting metal is then crushed and injected into a fluidized bed reactor to obtain chlorosilanes, which are then hydrolyzed in water, releasing hydrochloric acid (HCl). After distillation and multiple purification steps, a series of siloxane structural units are produced, ultimately forming important siloxane polymers.

Siloxane polymers are composed of different types of compounds, including traditional silicone oils, water-soluble polymers, oil-soluble polymers, fluorinated polymers, and polymers with various solubilities. They exist in various forms, from low-viscosity fluids to elastic elastomers and synthetic resins.

During the production process, involving the hydrolysis of chlorosilanes and the polycondensation of various compounds, organosilicon manufacturers must ensure the removal of all unnecessary residues and particles to ensure the quality of the final product. Therefore, stable, efficient, and easy-to-maintain filtration solutions are essential.

Customer Requirements

Organosilicon manufacturers need more effective methods for separating solids and trace liquids. The production process uses sodium carbonate to neutralize hydrochloric acid, which generates residual water and solid particles that need to be effectively removed. Otherwise, the residues will form gels and increase the viscosity of the final product, significantly affecting product quality.

Typically, removing residues requires two steps: separating solids from the organosilicon intermediate, and then using chemical additives to remove residual water. Organosilicon manufacturers desire a more efficient system that can remove solids, trace water, and gel particles in a single-step operation. If achieved, the company could simplify its production process, reduce by-product waste, and improve production efficiency.

Solution

The SCP series depth filter modules from Great Wall Filtration can remove almost all residual water and solids through adsorption, without causing significant pressure drop.

The nominal filtration accuracy of the SCP series depth filter modules ranges from 0.1 to 40 µm. Through testing, the SCPA090D16V16S model with an accuracy of 1.5 µm was determined to be the most suitable for this application.

The SCP series depth filter modules are composed of pure natural materials and charged cationic carriers. They combine fine cellulose fibers from deciduous and coniferous trees with high-quality diatomaceous earth. Cellulose fibers have strong water absorption capacity. Additionally, the ideal pore structure can capture gel particles, providing optimal performance and high efficiency.

SCP Series Depth Filter Module System

The modules are installed in a stainless steel closed module filtration system that is easy to operate and clean, with a filtration area ranging from 0.36 m² to 11.7 m², offering customizable solutions for various applications.

Results

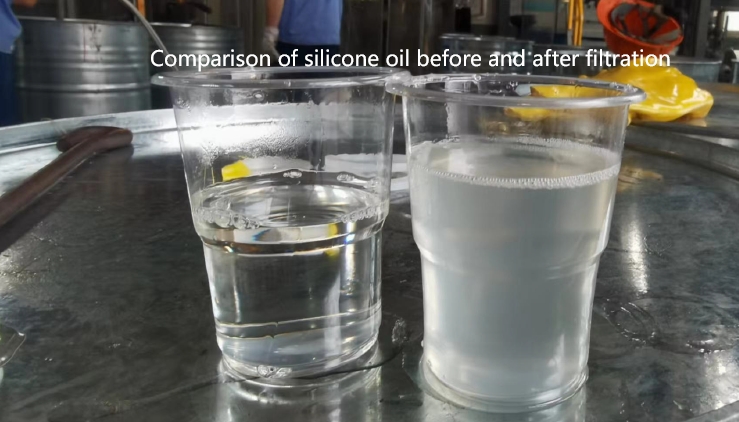

Installing the SCP series depth filter modules effectively removes solids, trace water, and gel particles from liquids. The single-step operation simplifies the production process, reduces by-product waste, and improves production efficiency.

Looking to the future, we believe the special performance of the SCP series depth filter modules will find more applications in the organosilicon manufacturing industry. “This is a truly unique product solution, with the ability to quickly and reliably remove water from another liquid being an ideal characteristic.”

For more information, please visit our website [https://www.filtersheets.com/], or contact us at:

- **Email**:clairewang@sygreatwall.com

- **Phone**: +86-15566231251

Post time: Aug-06-2024