High Quality Stacking Filters - Lenticular filter modules – Great Wall

High Quality Stacking Filters - Lenticular filter modules – Great Wall Detail:

Applications

• Liquid Decarburization and Decolorization

• Pre-filtration of Fermentation liquor

• Final Filtration (Germ Removal)

Material of Constructions

Depth Filter Sheet :Cellulose Fiber

Core/Separator: Polypropylene (PP)

Double O Ring or Gasket: Silicone, EPDM, Viton, NBR

Operating Conditions Max. Operating temperature 80℃

Max. Operating DP: 2.0bar@25℃ / 1.0bar@80℃

| Outer Diameter | Construction | Seal Material | Removal Rating | Connection Type |

| 8=8″

12=12″ 16 = 16″ |

7=7 Layer

8=8 Layer 9=9 Layer 12=12 Layer 14=14 Layer 15=15 Layer 16=16 Layer |

S= Silicone

E=EPDM V=Viton B=NBR |

CC002 = 0.2-0.4µm

CC004 = 0.4-0.6µm CC100 = 1-3µm CC150 = 2-5µm CC200 = 3-7µm |

A = DOE with gasket

B = SOE with O-ring |

Features

It can be washed under certain conditions to extend the service life

The operation is simple and reliable,and the solid outer frame design prevents the filter element from being damaged during installation and disassembly

Heat disinfection or hot filter fluid has no adverse effect on the filter board

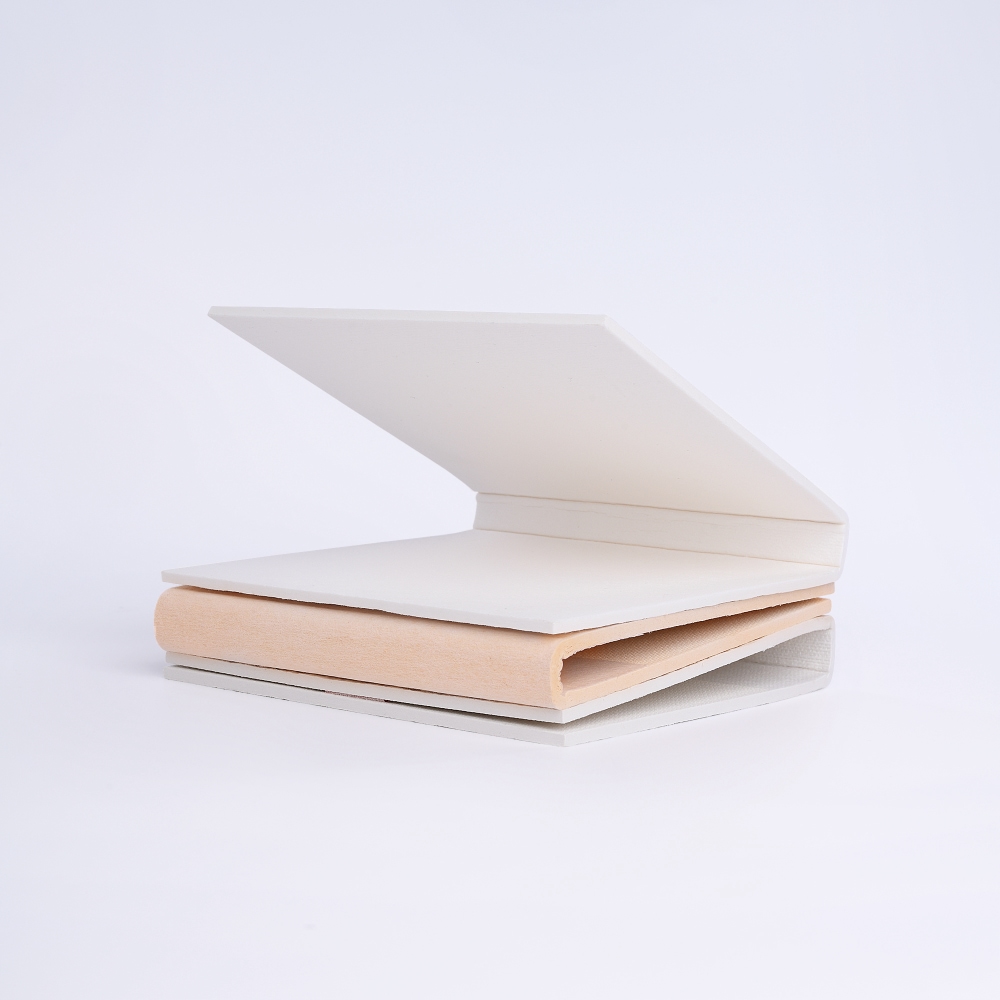

Product detail pictures:

Related Product Guide:

Dedicated to strict high-quality management and considerate purchaser support, our experienced employees members are usually available to discuss your specifications and be certain full shopper satisfaction for High Quality Stacking Filters - Lenticular filter modules – Great Wall , The product will supply to all over the world, such as: Azerbaijan, Norway, Zambia, We have now a good reputation for stable quality goods, well received by customers at home and abroad. Our company would be guided by the idea of "Standing in Domestic Markets, Walking into International Markets". We sincerely hope that we could do business with car manufacturers, auto part buyers and the majority of colleagues both at home and abroad. We expect sincere cooperation and common development!

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.