Factory wholesale Cutting Fluid Filter Paper – Industrial non-woven filter paper for Cutting fluid – Great Wall

Factory wholesale Cutting Fluid Filter Paper – Industrial non-woven filter paper for Cutting fluid – Great Wall Detail:

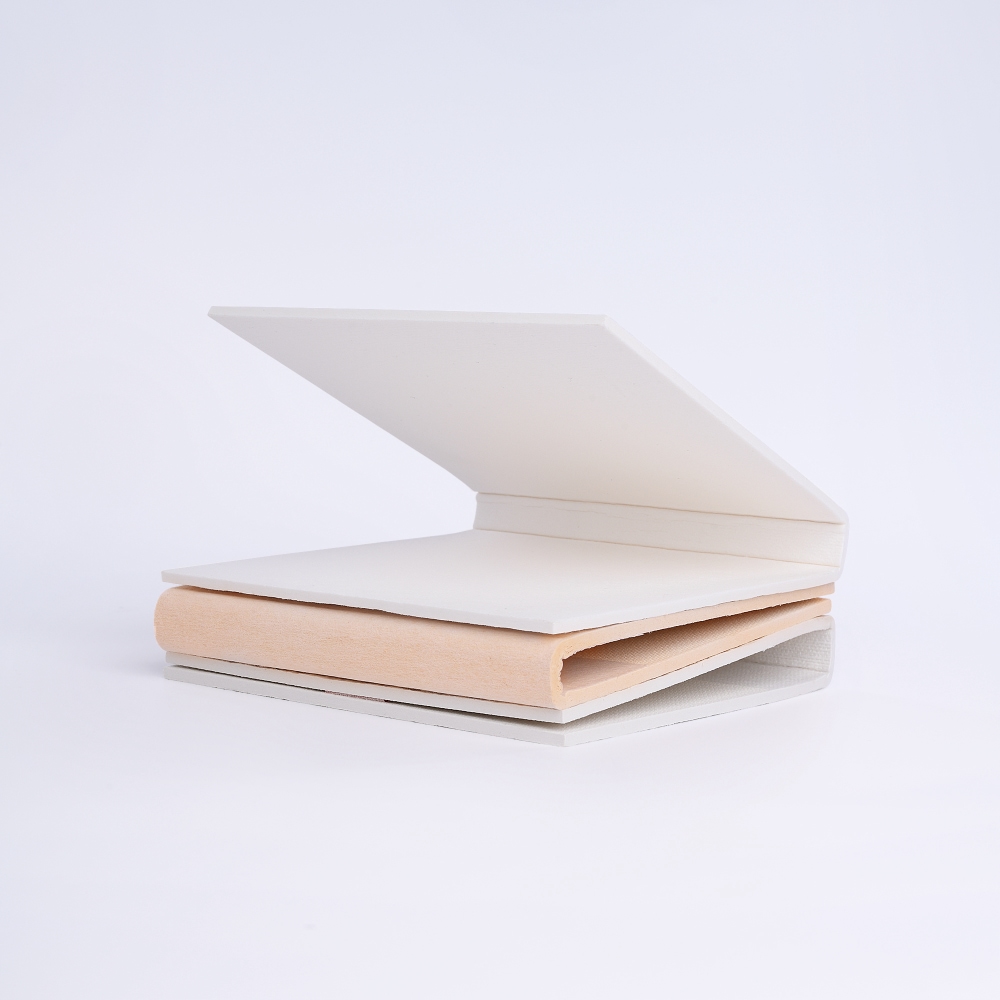

Industrial non-woven filter paper

The non-woven filter paper produced by our company is used to filter metal particles, iron sludge and other dross in cutting fluid, emulsion, grinding fluid, grinding fluid, drawing oil, rolling oil, cool fluid, cleaning fluid

When purchasing filter paper , There are two questions that need to be clarified :

1.Determine the material and precision of the filter paper

2 .The dimensions of the filter paper roll and the inner diameter of the center hole you need to make the filter paper into a filter bag , please provide the size drawing) .

Our non-woven filter paper Advantages

1. High tensile strength and small coefficient of variation. Jessman filter paper adopts fiber netting process and forming reinforcement to enhance the tensile strength and keep the initial strength and in-use strength basically unchanged.

2. Wide range of accuracy and high efficiency. The combination of chemical fiber raw materials and polymer film can meet the different precision requirements of users.

3. The filter material is generally not corroded by industrial oil, and basically does not change the chemical properties of industrial oil. It can be used normally in the range of -10°C to 120°C.

4. High horizontal and vertical strength, good burst resistance. It can withstand the mechanical force and temperature influence of the filter equipment, and its wet breaking strength will not decrease basically.

5. Large porosity, low filtration resistance, and large throughput. Improve filtration efficiency and shorten working time.

6. Strong dirt holding capacity and good oil cutting effect. It can be used for oil-water separation, prolong the service life of chemical oil, reduce the consumption of filter materials and reduce the cost of filtration.

7. Filter materials of different widths, materials, densities and thicknesses can be customized, suitable for various working environments.

Please refer to the application guide for additional information.

Filter paper performance parameters

|

Model

|

Thickness (mm)

|

Weight (g/m2)

|

|

NWN-30

|

0.17-0.20

|

26-30

|

|

NWN-N30

|

0.20-0.23

|

28-32

|

|

NWN-40

|

0.25-0.27

|

36-40

|

|

NWN-N40

|

0.26-0.28

|

38-42

|

|

NWN-50

|

0.26-0.30

|

46-50

|

|

NWN-N50

|

0.28-0.32

|

48-53

|

|

NWN-60

|

0.29-0.33

|

56-60

|

|

NWN-N60

|

0.30-0.35

|

58-63

|

|

NWN-70

|

0.35-0.38

|

66-70

|

Gram weight: (regular) 20, 30, 40, 50, 60, 70, 80, 90, 100, 120.(Special) 140-440

Size: 500mm—–2500mm (the specific width can be adjusted)

Roll length: according to customer requirements

Roll inner hole: 55mm, 76mm, 78mm or according to customer requirements

Note:After the material of the filter paper is selected, it is necessary to determine the width of the filter, the roll length or outer diameter, the material and inner diameter of the paper tube .

Filter Paper Applications

Grinding machine processing

Mainly used for cylindrical grinder/internal grinder/centerless grinder/surface grinder (big water grinder)/grinder/honing machine/gear grinder and other CNC roller grinders, cutting fluid, grinding fluid, grinding fluid, honing fluid and other industrial oils Class filtering.

Iron and steel metallurgical processing

It is mainly used to filter the emulsion, coolant and rolling oil in the process of cold-rolled/hot-rolled plates, and it is used in conjunction with negative pressure filters such as Hoffmann.

Copper and aluminum processing

It is mainly used to filter emulsion and rolling oil during copper rolling/aluminum rolling, and is used in conjunction with precision plate filters.

Auto parts processing

It is mainly used in conjunction with the cleaning machine and (positive pressure, negative pressure) flatbed paper tape filter to filter cleaning fluid, cooling fluid, cutting fluid, etc.

Bearing processing

Including filtering cutting fluid, grinding fluid (belt), honing fluid, emulsion and other industrial oils. Applied in sewage treatment Water filtration including sewage pools, tap water pools, etc., centralized filtration systems, or used in conjunction with filtration equipment.

Contact us for more information, we will provide you better products and best service .

Product detail pictures:

Related Product Guide:

The key to our success is "Good Product Quality, Reasonable Price and Efficient Service" for Factory wholesale Cutting Fluid Filter Paper – Industrial non-woven filter paper for Cutting fluid – Great Wall , The product will supply to all over the world, such as: Poland, Cyprus, South Africa, With the best technological support, we have tailored our website for the best user experience and kept in mind your ease of shopping. we ensure that the best reaches you at your doorstep, in the shortest possible time and with the help of our efficient logistical partners i.e DHL and UPS. We promise quality, living by the motto of promising only what we can deliver.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.