Europe style for Water Pad Filter - Pharmaceutical Sheets for blood products industry – Great Wall

Europe style for Water Pad Filter - Pharmaceutical Sheets for blood products industry – Great Wall Detail:

BIOH series paperboards Introduction

BIOH series paperboards are made of natural fibers and perlite filter aids , and are used for composites with high liquid viscosity and high solid content .

BIOH series paperboards Features

1.FeaturesHigh throughput , significantly improve filtration efficiency .

The special fiber structure and filter aids inside the cardboard can efficiently filter impurities such as microorganisms and ultrafine particles in the liquid .

2.The application is flexible , and the product can be used in different filtering scenarios :

Fine filtration to reduce microorganisms

Pre-filtration of protective membrane filtration .

Haze-free filtration of liquids before storage or filling .

3.Mouth has high wet strength , allows cardboard to be recycled to reduce costs , and withstands pressure transients in filtration cycles .

BIOH series paperboards Product parameters

| Model | Filtration rate | Thickness mm | Retention particle size um | Filtration | Dry burst strength kPa≥ | Wet burst strength kPa≥ | Ash %≤ |

| BlO-H680 | 55′-65‘ | 3.4-4.0 | 0.2-0.4 | 23-33 | 450 | 160 | 52 |

| BlO-H690 | 65′-80′ | 3.4-4.0 | 0.1-0.2 | 15-29 | 450 | 160 | 58 |

①The times it takes for 50ml of pure water to pass through a 10cm filter cardboard at room temperature and under 3kPa pressure .

②The amount of pure water that passes through 1m of cardboard in 1 minute under normal temperature and 100kPa pressure .

BIOH series paperboards Instructions in use

1. Installation

Gently insert the cardboard into the plate and frame filters , avoiding knocking , bending and friction .

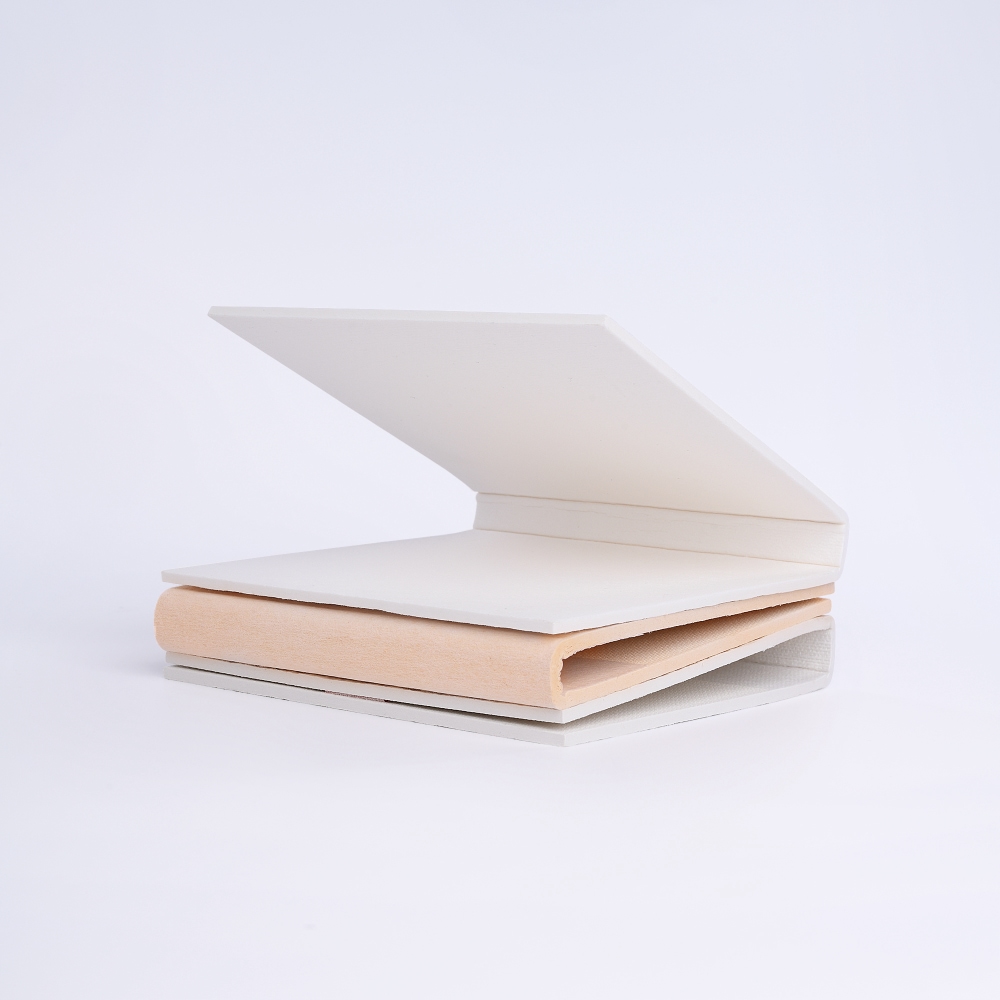

The cardboard installation is directional . The rougher side of the cardboard is the feeding surface , which should be opposite to the feeding plate during installation ; the smooth surface of the cardboard is texture , which is the discharging surface and should be opposite to the discharging plate of the filter . If the cardboard is reversed , the filtration capacity will be reduced .

Please do not use damaged cardboard .

2 Hot water disinfection (recommended) .

Before formal filtration , use purified water above 85°C for circulating rinsing and disinfection .

Duration : When the water temperature reaches 85°C or more , cycle for 30 minutes .

The filter outlet pressure is at least 50kpa (0.5bar ) .

Steam sterilization

Steam Quality : Steam must not contain other particles and impurities .

Temperature : up to 134°C (saturated water vapor ) .

Duration : 20 minutes after the steam has passed through all the filter cardboards .

3 Rinse

Rinse with 50 L/i of purified water at a flow rate of 1.25 times .

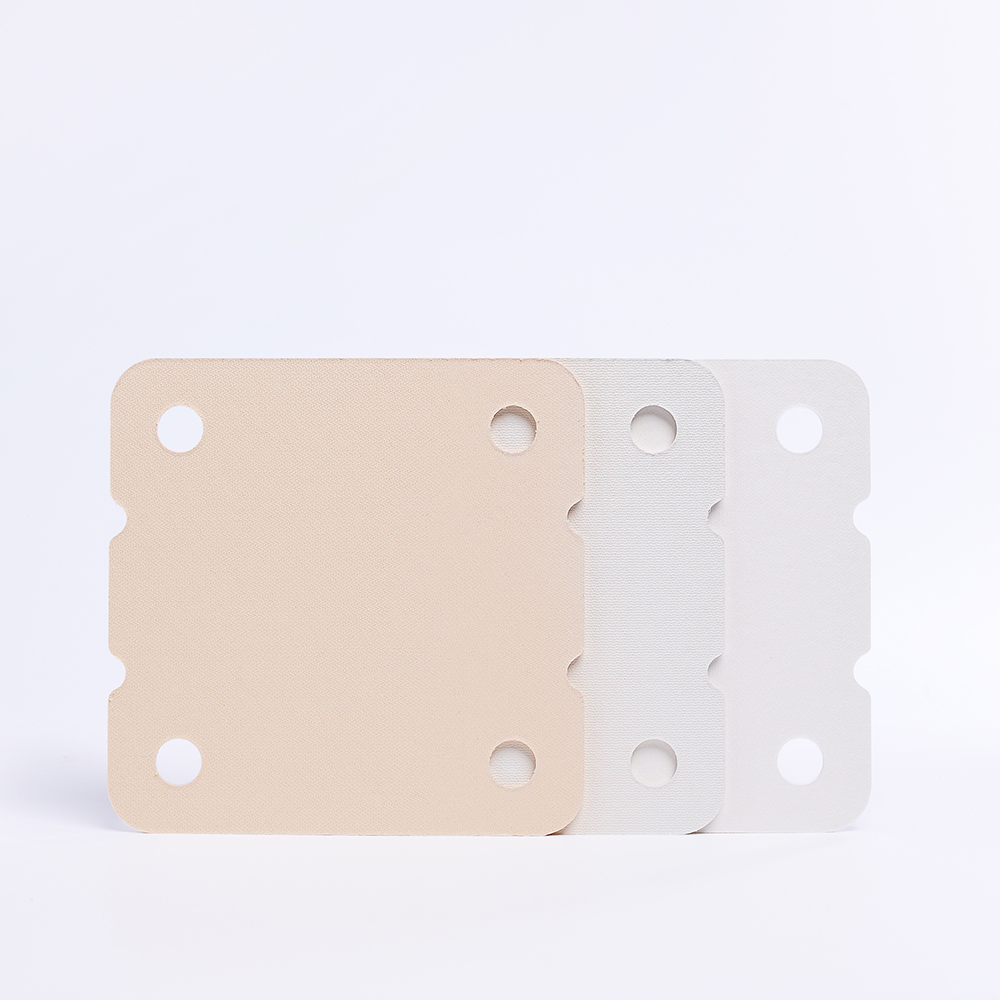

Shape and Size

The filter cardboard of the corresponding size can be matched according to the equipment currently used by the customer , and other special processing shapes can also be customized , such as round , special-shaped , perforated , draped , etc .

Product detail pictures:

Related Product Guide:

We are going to make every single effort for being excellent and excellent, and accelerate our ways for standing while in the rank of international top-grade and high-tech enterprises for Europe style for Water Pad Filter - Pharmaceutical Sheets for blood products industry – Great Wall , The product will supply to all over the world, such as: Tajikistan, Mauritania, Benin, We aim to build a famous brand which can influence a certain group of people and light up the whole world. We want our staff to realize self-reliance, then achieve financial freedom, lastly obtain time and spiritual freedom. We do not focus on how much fortune we can make, instead we aim to obtain high reputation and be recognized for our products. As a result, our happiness comes from our clients satisfaction rather than how much money we earn. Ours team will do best for you always.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!