Europe style for Micron Filter Paper - Creped Filter Papers with large filtering area – Great Wall

Europe style for Micron Filter Paper - Creped Filter Papers with large filtering area – Great Wall Detail:

Applications:

• Food & beverage

• Pharmaceutical

• Cosmetics

• Chemical

• Microelectronics

Features

-Made of refined pulp and cotton

-Ash content < 1%

-Wet-strengthened

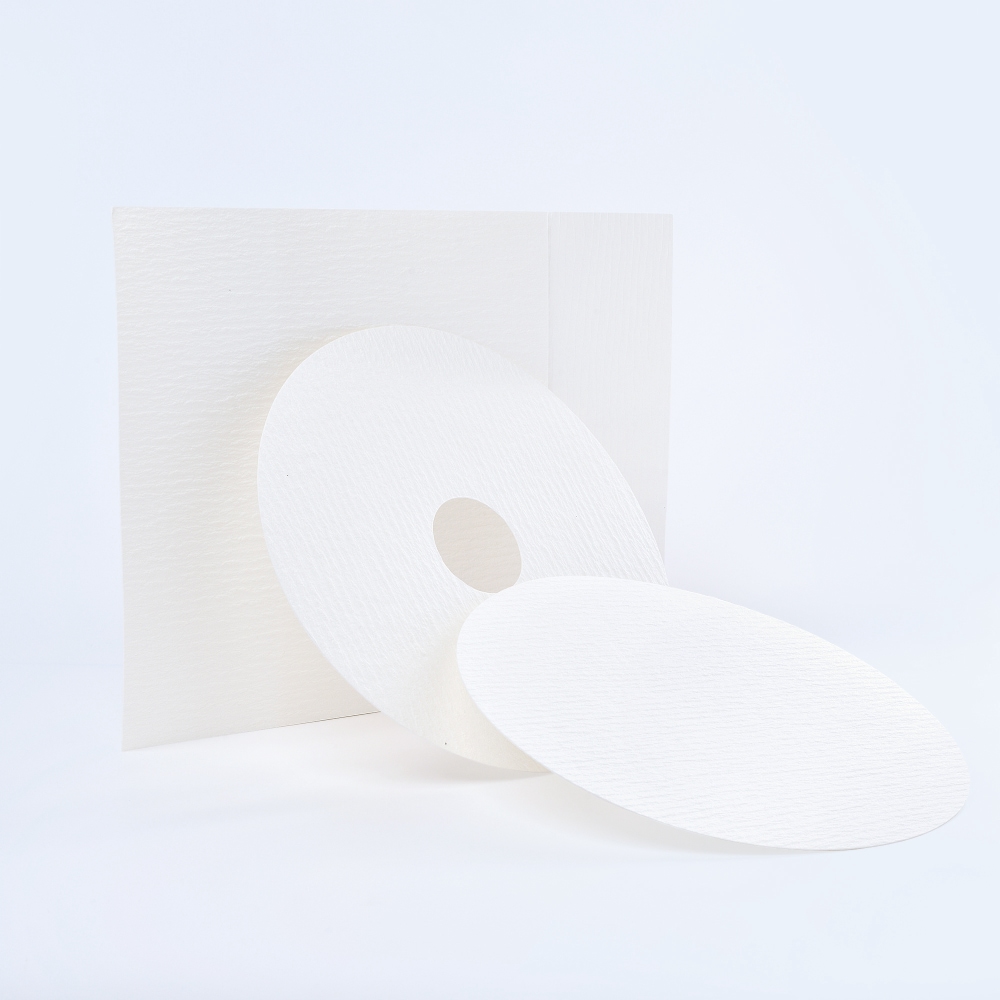

- Supplied in rolls, sheets, discs and folded filters as well as customer-specific cuts

How Do Filter Papers Work?

Filter papers are actually depth filters. Various parameters influence their effectiveness: Mechanical particulate retention, absorption, pH, surface properties, thickness and strength of the filter paper as well as the shape, density and quantity of particles to be retained. The precipitates deposited on the filter form a “cake layer”, which – depending on its density – increasingly affects the progress of a filtration run and decisively affects the retention capability. For this reason, it is essential to select the right filter paper to ensure effective filtration. This choice also depends on the filtration method to be used, among other factors. In addition, the amount and properties of the medium to be filtered, the size of the particulate solids to be removed and the required degree of clarification are all decisive in making the right choice.

Great Wall pays particular attention to continuous in-process quality control; additionally, regular checks and exact analyses of raw material and of each individual finished product

assure constant high quality and product uniformity.

Please contact us, we will arrange technical experts to provide you with the best filtration solution

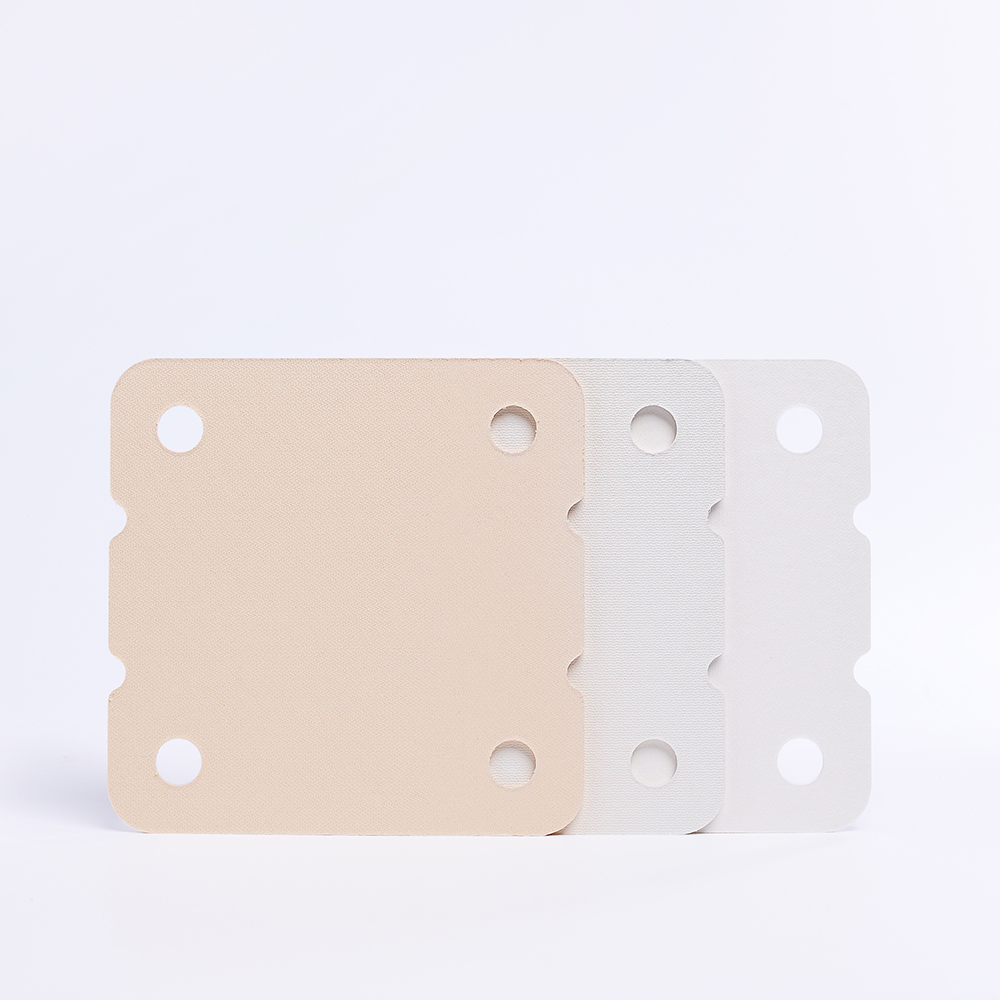

Product detail pictures:

Related Product Guide:

Our business aims to operating faithfully, serving to all of our clients , and working in new technology and new machine continuously for Europe style for Micron Filter Paper - Creped Filter Papers with large filtering area – Great Wall , The product will supply to all over the world, such as: Albania, Greek, Canberra, We provide OEM services and replacement parts to meet the varying needs of our customers. We give competitive price for quality solutions and we are going to make certain your shipment is handled quickly by our logistics department. We sincerely hope to have the opportunity to meet with you and see how we can help you further your own business.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!